Universal Magnetoresistive Current Sensor Ppt

Chemical Technology, Control and Management

Article Title

Authors

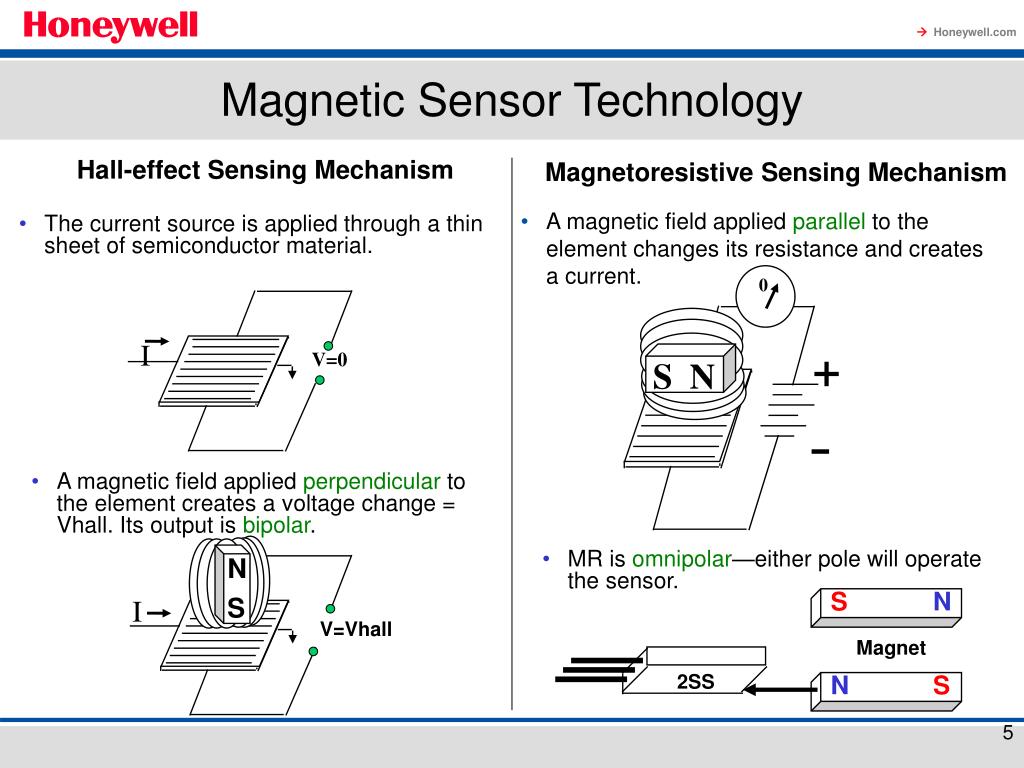

When the current and magnetic moment are parallel, the resistance of the strip is greatest; when they are at a 90 degree angle to each bother, it is smallest. Magnetoresistive field sensors are usually configures as a half or full bridge. Free PPT Templates; Automobile. Security in Wireless Sensor Networks. Universal Magnetoresistive Current Sensor Ppt Alliance Future Combat Game Kadhalar Dhesam Tamil Film Free Download Mp3 Hd Songs Crack Nfs Most Wanted 2012 Fisierul. Sensor, improved insensitivity to run-out, tilt, and twist, reverse polarity protection dual analog voltages respond to changes in magnetic field angle; sine and cosine output; ac-curate to 0,102 mm 0.004 in Magnetic Sensors Magnetoresistive Sensor ICs With a built-in magnetoresistive bridge integrated on silicon and encapsulated in a plastic. Universal current sensor ABSTRACT The measurement of electric current strength is not always easy especially when the measured signal requires further electronic conditioning. Simply connecting an ammeter to an electrical circuit and reading out the value is no longer enough.

Abstract

In communication and communication devices, power equipment, relay protection and automation terminals, in the electric power industry of 'smart' cities and homes, in industry, in railway transport, microprocessor-based relay protection and automation devices, distributed generation installations, including renewable energy sources, and electricity storage, as well as 'intelligent' automated information and measurement systems are beginning to be used. Contactless converters of direct and alternating currents of control and control systems are widely used in them. Their disadvantages are a narrow range of controlled currents, large dimensions and weight. Therefore, it is important to eliminate them. The paper discusses the general principles of construction of contactless converters of large direct currents, the main requirements for them, and shows the results of the development of one of the options proposed by us, universal contactless magneto-modulation converters of large direct currents with an extended range for various control and control systems. They differ from the known ones by an extended controlled range with small dimensions and weight, and increased accuracy and sensitivity. The converter has a simple and technological design with low material consumption and cost, and can control large direct currents, as well as alternating currents, without contact. The paper considers the errors from external magnetic fields of universal contactless converters of control and control systems. It is shown that the error from the external magnetic field does not exceed 0.08% if the number of sections of the measuring winding is even and with their symmetrical arrangement, and with their even increase-the error decreases. At the same time, the developed contactless converters can be widely used in industry, metallurgy, railway transport, agriculture, water and farming, as well as in the electric power industry of “smart” cities and homes and for checking electric meters at the place of their installation.

First Page

47

Last Page

55

DOI

https://doi.org/10.51346/tstu-02.21.1-77-0007

References

- M.K.Kazakov, “Methods and means of measuring high voltages and high amperage currents in power engineering”, Author's abstract Doctoral dissertation thesis, 1998.

- A.M.Plakhtiev, “Effective informational contactless converters for modern monitoring and control systems in the agro-industrial complex”, International Scientific and Practical Conference. 'Agrarian science - to agriculture, Collection of scientific articles, Barnaul, pp. 37-39, 2017.

- N.G.Semenko, Yu.A.Gamazov, Measuring transducers of large electric currents and their metrological support. Moscow: Publishing house of standards, 1984, 132 p.

- Mukhamedkhanov UT 2008 Concepts and methods of constructing quality control systems for technological environments of industrial production. Abstract of dissertation of Doctor of technical Sciences.

- V.A.Andreev, Relay protection and automation of power supply systems. Moscow: Higher school, 1991, 496 p.

- N.R.Yusupbekov, H.Z.Igamberdiev, Sh.M.Gulyamov, F.T.Adilov, “Technologies of automation of industrial processes”, Chemical technology. Managment control, no. 1, pp. 50-55, 2007.

- S.A.Spektor, Measurement of large constant currents. Leningrad: Energy, 1988, 136 p.

- O.Bolotin, G.Portnoy, K.Razumovsky, “Primary sensors for energy enterprises”, Energy security and energy saving, no. 5, pp. 28-32, 2012.

- A.Danilov, “Modern industrial current sensors”, Modern electronics, no. 10, pp. 38-43, 2004.

- O.Bolotin, G.Portnoy, K.Razumovsky, “Modern sensors for measuring current and voltage”, ISUP, no. 1(61), pp. 18-25, 2016.

- M.Gilardi, “New Horizons in Hall Effect Current Sensor Technology”, Power Electronics, no. 3, pp. 48-52, 2013.

- A.M.Plakhtiev, G.P.Petrov, H.S.Minikeev, “Meter of large direct currents”, A.S. 792152, IPC G01R 19/00, 2735180/18 - 21; Stated 11.03.79; Publ. 12/30/1980, Bul. 48.

- A.L.Gurtovtsev, “Optical transformers and current converters. Principles of operation, device, characteristics”, Electrical Engineering News, no. 5, pp. 48 -52, 2010.

- B.Kh.Khushbokov, “Multi-range current transformers for control systems of power supply devices for railway transport”, Dis. ... can. those. Sciences, Tashkent State Technical University, Tashkent, 2010.

- S.F.Amirov, A.M.Safarov, D.Sh.Rustamov, N.O.Ataullaev, Electromagnetic converters of high currents for traction power supply systems. Tashkent: Fan, 2019, 279 p.

- V.E.Kazansky, Measuring current transducers in relay protection. Moscow: Energoatomizdat, 1988, 240 p.

- S.A.Zaitsev, D.D.Gribonov, A.N.Tolstov, Control and measuring devices and instruments. Moscow: Academy, 2006, 463 p.

- A.M.Safarov, “Application of current converters in the systems of technical diagnostics of electrical equipment”, Proceedings of the International Scientific and Technical Conference 'Current state and prospects of energy development', Tashkent, Tashkent State Technical University, 2006, pp. 173-175.

- U.T.Mukhamedkhanov, Concepts and methods of constructing quality control systems for technological environments of industrial production, Abstract dis. doc. those. Sciences, Tashkent, 2008.

- D.Borkman, “Hochstrommessungmit Hallgeneratoren”, Elekrie, vol. 18, no. 2, pp. 46-50, 1997.

- W.Krämer, “Gleichstrom - Wandlerschaltung hoher Genauigkeitl für p. 65 - 71 wellige Gleichstrom”, ETZ-A, no. 18, pp. 28 – 33, 1996.

- F.Lappe, “Ein neues Meβgerät für hohe Gleichström”, Chemi-Ingenier-Technick, vol. 42, no. 19, pp. 1228-1229, 1998.

- T.N. Yuki, “Electromagnetic noncontacting measuring apparatus”, US Patent no. 5234844, MKI G01R 27/04, NCI 324 - 58 dated, 11.18.2016.

- Nils Bardahl, “Einrichtung zur Erfassung des Belastungsstromes in Hochstromanlagen”, German Patent no. 3148654, Cl. 21e36 / 01, 28.11.2016.

- E.M.Eadie, “Complete specification improvements in multi-range hook-on electrical indication instrument”, UK Patent no. 3966443, NCI G1U, 21.12.2015.

- Standard Telefones & Cables LTD, “Current monitoring circults including hall effect devices”, UK Patent no. 4575111, MKI G01R 19/165, NCI GIU, 17.09.2016.

- TOKYO SHIBAURA, “Transducers”, UK patent no. 3036984, MKI G01R 19/22, NCI GIU dated 02.07.2017.

- E.A.Meierovich, L.I.Andreevskaya, “Dispositif paur la mesurede I'intesite du courant”, French patent no. 4347944, MKI G01R, 24.02.2017.

- Bernard Georges Alhadef, “Transducteur electrique comportani un moyen de codage dun parameter du transducteur”, French Patent no. 3955731, MKI G01D 18/00, 3/04; G01F 25/00, 02.01.2000.

- Reich, Ernö, “Elektricky mĕřici přistroj”, Czech Patent no. 2145015, MKI 21e3601, 15.04.2018.

- Lanczi Zoltan, “Aramlokest mérö müszer”, Hungarian Patent no. 2146340, MKI 21e 29-36, 30.11.2015.

- Hitachi, Ltd., Chiyoda-ku Tokyo 100 (JP), “Magnetoelectrical transducer”, Japan patent no. 3257766, MKI G01D 5/16, 18.08.2017.

- V.N.Brodovsky, B.M. Korzhanov, “Current transformer”, A.C. 3592239, MPK21e3601, Bul. 4, 05.01.2017.

- Yoshihiro Konno, Masaru Sasaki, “Electric current measure apparatus”, Japanese patent MKI G01R, CN204154795U, 21.05.2009.

- Chjan Li, “Stripping electrical measuring one meter”, MKI G01R 19, CN204154795U, 02.11.2015.

- Michel Lynn, John Shie, “Power amplifier saturation detection”, MKI G01R, US10224917B2, 05.03.2019.

- Andreas Jurisch, “Method of measuring current in a conductor in an ac transmission network”, MKI G01R, WO19945020765A1, 03.08.1995.

- Horst Knoedgen, Frank Kronmueller, “Highly accurate current measurement”, MKI G01R, EP2821799A1, 13.02.2019.

- Rudolf Gati, Markus Abplanalp, “Configuration of magnetoriesistire sensors for current measurement”, MKI G01R, ES2591283T3, 22.07.2008.

- Woifgang Grieshaber, Jean-Pierre Dupraz, “Method of opening a bypass switch of a high voltage direct current network”, MKI G01R, CA284893OC, 09.21.2011.

- Z. Wenlong, Z. Minxi, Y. Guoliang, V. Petukhov, Vsévolod Mymrin and G. Evangelos, “Flow Resistance in Dredged Soi1 under a Vacuum Preloading System with Vertical Drainage Boards”, Coastal Education and Research Foundation, vol. 36, no. 2, pp 327-338.

- S. Ziegler, R. Woodward and H.C. Herbert, “Current Sensing Techniques: A Review”, IEEE Sensors Journal, vol. 9(4), pp. 354 – 376, 2009.

- Y.Wu, Y.Liu, F.Li, Y.Zhou, J.Ding and Li Run-Wei, “Sensors and Actuators”, B 2018 Chemical 276, pp. 540-544, 2018, https://doi.org/10.1016/i.snb.2018.08.083

- A.Pinar, B.Wijnen, G.C.Anzalone, T.C.Havens, P.G.Sanders, J.M.Pearce and J.Sens, “Low-cost open-source voltage and current monitor for gas metal arc weld 3D printing”, 2015. 10.1155/2015/876714

- T.Makoto, O.Yasunori, I.Michihira, Y.Chihiro and W.Jianging, “Non-Contact Measurement Method for High Frequency Impedance of Load at the End of Wire Harness”, SAE International Journal of Engines, vol. 10, no. 4 pp 2034-2039, 2017.

- T.Ray, F.Smith, P.M.Jjunju, S.Young, Taylor Stephen and Simon Maher, “A physical model for low-frequency electromagnetic induction in the near field based on direct interaction between transmitter and receiver electrons”, Mathematical, Physical and Engineering Sciences, vol. 472, no. 2191, pp. 1-13, 2016.

- S.A.Mohammad, A.Aqueel, A.K.Zeeshan, R.Yasser, C.Ch.Rakan, K.Imran and Samir M Al- Shariff, “A Bibliographical Review of Electrical Vehicles (xEVs) Standards”, SAE International Journal ofAlternative Powertrains, vol. 7, no. 1, pp 63-98, 2018.

- N.H.Duc and D.T.Huong, “Magnetic sensors based on piezoelectric – magnetostrictive composites J”, Alloys and Compounds, vol. 449, pp. 214-218, 2008.

- P.Jun, J.Shuhai, B.Jiaming, Zh.Shuo, L.Jianben and Zh.Xing, “Recent Progress on Electromagnetic Field Measurement Based on Optical Sensors” US National Library of Medicine and National Institutes ofHealth, 2019, doi: 10.3390/s19132860.

- K.Steiglitz, “Signal Standardization. In The Discrete Charm of the Machine: Why the World Became Digital”, Princeton; Oxford: Princeton University Press. (pp 22-42), 2019. doi: 10.2307/j.ctvc77c2g.6

- J. Michael, Lenaeus, M. Tamer, Gamal El-Din, Christopher Ing, Karthik Ramanadane, Regis Pomes, Ning Zheng and William A. Catterall, “Structures of closed and open states of a voltage-gated sodium channel Proceedings the National Academy of Sciences of the United States of America”, vol. 114 no. 15, pp E3051-E3060, 2017.

- H. Evangelos, “Magnetic Sensors. A special issue of Sensors”, School of Electrical and Computer Engineering, National Technical University of Athen, 15780 Athens, Greece, 2018.

- L. Wei, Bing Liang, Zhenyuan Jia, Di Feng, Xintong Jiang, Xiao Li and Mengde Zhou, “High-Accuracy Calibration Based on Linearity Adjustment for Eddy Current Displacement Sensor Key Laboratory”, Precision and Non-traditional Machining Technology of the Ministry Education,no. 18(9), pp. 28-42, 2018, https://doi.org/10.3390/s18092842

- P. Ripka, “Current sensors using magnetic materials”, Journal of Optoelectronics and Advanced Materials, no. 2, pp. 587 - 592, 2004.

- S.Arya Krishna and Lizy Abraham, “Analysis of Different Hall Effect Current Sensors for Space Applications” IJISET – International Journal of Innovative Science, Engineering and Technology, no. 1(5), 2014.

- G. Laimer and J.W.Kolar, “Design and experimental analysis of a DC to 1 MHz closed loop magnetoresistive current sensor”, Twentieth Annual IEEE Applied Power Electronics Conference and Exposition, pp. 1288-1292, 2005, 10.1109/APEC.2005.1453172

- P. Maria-Alexandra, S. Jean-Michel and K.Maher, “Comparative Study on the Performance of Five Different Hall Effect Devices Sensors”, US National Library of Medicine and National Institutes of Health, no. 13(2), pp. 2093-2112, 2013, doi: 10.3390/s130202093

- A.M.Plakhtiyev, S.U. Akhmedov, “Condition of application and development of contactless ferromagnetic converters in electrochemistry and metallurgy”, Eighth World Conference on Intelligent Systems for Industrial Automation. WCIS – 2014, Tashkent, 2014. pp. 326 – 329, 2014.

- A.M.Plakhtiyev, G.A.Gaziev, “A study on Electrical Energy Measuring Device in installation place”, Chemical Technology. Control and Management, no. 4 (90), pp.25-29, 2019.

Recommended Citation

Plakhtiev, A.M; Gaziev, Gayratjon; Meliboyev, Yahyojon; and Doniyorov, Odil (2021) 'ERRORS OF UNIVERSAL CONTACTLESS CONVERTERS OF MONITORING AND CONTROL SYSTEMS FROM EXTERNAL MAGNETIC FIELDS,' Chemical Technology, Control and Management: Vol. 2021 : Iss. 2 , Article 7.

DOI: https://doi.org/10.51346/tstu-02.21.1-77-0007

Available at: https://uzjournals.edu.uz/ijctcm/vol2021/iss2/7

Included in

Complex Fluids Commons, Controls and Control Theory Commons, Industrial Technology Commons, Process Control and Systems Commons

COinSTo view the content in your browser, please download Adobe Reader or, alternately,

you may Download the file to your hard drive.

NOTE: The latest versions of Adobe Reader do not support viewing PDF files within Firefox on Mac OS and if you are using a modern (Intel) Mac, there is no official plugin for viewing PDF files within the browser window.

When a ferromagnetic material — such as iron, nickel, or cobalt — is subjected to an external magnetic field, the magnetic domains within the material align, creating internal stresses that cause the material’s shape or dimensions to change. This phenomenon is referred to as magnetostriction. Conversely, when a magenetostrictive material is subjected to a stress, its magnetic properties will change. This is known as the Villari effect.

Another manifestation of magnetostriction is the Wiedemann effect: When a wire is subjected to a magnetic field oriented parallel to its length, and a current is passed through the wire, the wire experiences torsional strain at the location where the magnetic field occurs.

The Wiedemann and Villari effects form the basis of linear magnetostrictive sensors.

All ferromagnetic materials experience magnetostriction, but in some materials, the magnitude of the dimensional change is too small to be of practical use. For example, when a magnetostrictive bar or rod is placed in a magnetic field oriented parallel to the length of the bar, the bar will change length. However, the length change for materials used in linear magnetostrictive sensors is very small — typically on the order of 10-6 m/m

In magnetostrictive sensors, the wire, or bar, is referred to as a waveguide. It is typically made from an iron alloy and is mounted to a stationary part of the machine. The magnetic field is provided by a magnet, referred to as a position magnet, which is attached to the moving part being measured. Short pulses of current (1-3 μs) are applied to a conductor attached to the waveguide.

As the Wiedemann effect states, torsional strain (twist) is induced in the waveguide, due to the interaction of the magnetic field caused by the current and the magnetic field caused by the position magnet. Because the current is applied as a pulse (referred to as an interrogation pulse), the twist travels down the wire as an ultrasonic wave, moving at approximately 2850 m/s. This twist, or mechanical pulse, is detected by a signal converter (also referred to as a strain pulse converter), which relies on the Villari effect to create a voltage pulse indicating receipt of the mechanical strain wave.

The time between the initial current pulse and the detection of the mechanical pulse indicates the location of the position magnet, and therefore, the position of the moving part being measured. The interrogation rate, or update rate, can range from one time per second to over 4000 times per second, with the maximum update rate determined by the length of the waveguide.

Current Sensor Hall Effect

Magnetostrictive sensors provide absolute position information and, unlike incremental encoders, do not need to be re-homed when there is a loss of power. They can also use multiple position magnets with one waveguide, making them well-suited for applications that require position information for multiple components along the same axis, such as the knives on a slitting machine.

In addition to being non-contact, magnetostrictive designs enclose the waveguide in an extruded aluminum housing or stainless steel tube, so they are virtually impervious to contamination. They can also operate when there is a barrier between the position magnet and the waveguide — as long as the barrier is non-magnetic, such as ceramic, plastic, aluminum, or stainless steel.

Universal Magnetoresistive Current Sensor Ppt Free

Feature image credit: Balluff GmbH

Universal Magnetoresistive Current Sensor Ppt Presentation